What is SIPP Technology?

Spray-In-Place Pipe (SIPP) is an advanced trenchless rehabilitation method that creates a seamless protective barrier directly on pipe interior surfaces. Our 100% VOC-free SIPP systems cure in 3-6 seconds, providing immediate return to service with no annular space loss - preserving full flow capacity while delivering exceptional chemical resistance.

How SIPP Works...

Advanced polymeric materials are precisely sprayed onto pipe interiors using specialized robotic equipment, creating a seamless protective barrier. The spray application cures almost instantly, forming a durable lining that can serve as either a protective coating or complete structural replacement.

SIPP Technology Options

Structural Linings

Best for: Complete pipe rehabilitation, host substrate replacement, extreme environments

-

Immediate cure times - 3-6 seconds from application to service

-

No annular space loss - maintains full pipe capacity (0.5mm to 25mm thickness)

-

Structural replacement - designed for pipes where substrate should be fully degraded

-

50+ year design protocol for long-term infrastructure solutions

Protective Coatings

Best for: Corrosion protection, chemical resistance, preventive maintenance

-

100% VOC-free polyurethane and epoxy formulas

-

Chemical resistance for concrete, steel, masonry, fiberglass substrates

-

Corrosion and wear-and-tear protection

-

Water and freeze-resistant formulations

Advanced Polymeric Materials

Polyurea Coatings

Most versatile SIPP solution with proven track record

-

3-6 second gel time with 100% solids formulation

-

Customizable formulations with amine ending blend resin

-

No annular space - preserves original flow rates

-

Oldest and most proven SIPP technology

Polyurethane Coatings

Perfect balance of cost-efficiency and durability

-

Polyol ending blend with multiple application support

-

Highly rated against chemical abrasion and corrosion resistance

-

Excellent for microbial buildups and seismic activity protection

-

Requires completely dry substrate surfaces for optimal performance

Epoxy Coatings

Gold standard in SIPP applications

-

Thermosetting epoxide polymer with amine curing agents

-

Fortified with ceramics for enhanced durability

-

2mm average thickness without impeding flow capacity

-

Excellent for high-heat and moisture-rich environments

-

Longer setup times (hours vs. minutes) for complex applications

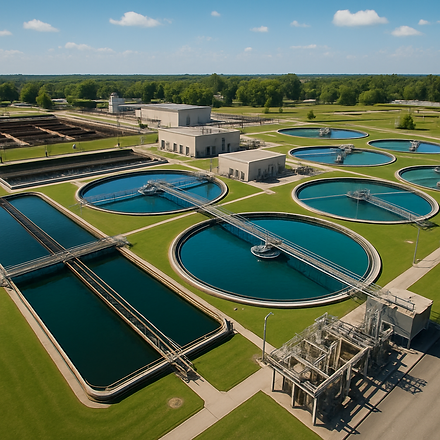

Diverse Infrastructure Applications

Pipe Rehabilitation:

-

Municipal storm and sanitary systems (1¼ inch to 72 inches diameter)

-

Industrial process piping and chemical transport lines

-

Treatment plant critical infrastructure

-

High-temperature and corrosive environments

Structural Applications:

-

Manholes and access structures - complete protective coating systems

-

Culverts and drainage systems - structural rehabilitation and protection

-

Industrial tanks and vessels - chemical-resistant protective barriers

-

Concrete, steel, and masonry substrates - comprehensive corrosion protection

Specialized Environments:

-

Oil, gas, and mining operations

-

Chemical processing facilities

-

Food service and institutional applications

-

Agricultural processing and storage systems

Key Advantages Over Traditional Methods

Immediate Results

-

3-6 second cure times - fastest return to service available

-

No downtime for curing processes

-

Immediate structural integrity upon application completion

Superior Performance

-

No annular space loss - maintains full pipe capacity

-

Customizable thickness from 0.5mm to 25mm based on application needs

-

Exceptional chemical resistance for harsh industrial environments

-

Twice the load resistance of the original piping when used as a structural replacement

Environmental Benefits

-

100% VOC-free formulations meeting environmental standards

-

No excavation required - eliminates surface disruption

-

Minimal site footprint and reduced project impact

-

Sustainable rehabilitation extends infrastructure life by decades

Cost-Effective Solutions

-

Fraction of traditional repair time - reduces labor and equipment costs

-

No excavation costs - eliminates restoration and traffic management

-

Immediate return to service - minimizes operational disruption

-

Long-term value through 50+ year service life

Problems We Solve

Structural Challenges

-

Complete host substrate replacement for severely degraded pipes

-

H2S oxidation and sulfuric acid corrosion damage

-

Biofilm buildups (FOG - fats, oils, grease) causing structural damage

-

Seismic activity and ground movement stress

Chemical and Environmental Issues

-

Extreme temperature applications (industrial processes)

-

High chemical concentration exposure

-

Microbial and biological attack resistance

-

Moisture-rich and corrosive environments

Operational Problems

-

Capacity reduction from buildup and corrosion

-

Infiltration and exfiltration issues

-

Emergency repairs requiring immediate return to service

-

Difficult access situations where excavation isn't feasible

Ideal Applications

Application Range

-

Pipe diameters: 1¼ inch to 72 inches

-

Thickness options: 0.5mm to 25mm customizable

-

Substrate compatibility: Concrete, steel, masonry, fiberglass, existing pipe materials

Performance Standards

-

AWWA Structural Classifications - Class I through Class IV applications

-

50+ year design life expectancy

-

ANSI/NSF/CAN 61 compliance for potable water applications

-

100% VOC-free environmental compliance

Cure Specifications

-

Gel time: 3-6 seconds

-

Full cure: Minutes (vs. hours for traditional methods)

-

Service readiness: Immediate upon completion

Technical Specifications

Pipe Diameter Range

-

Traditional CIPP: 75mm to 1200mm

-

UV-Cured CIPP: Up to 32 inches (800mm)

Installation Types

-

Full-length pipe rehabilitation

-

Targeted spot repairs

-

Partial liner installations

Material Standards

-

ASTM International certified products

-

VOC-free resin systems

-

Felt and fiberglass composite construction

Performance Standards

-

50+ year design life expectancy

-

Meets new pipe performance specifications

-

Full structural load capacity restoration

Licensed Partnerships & Industry Leadership

Our licensed partnerships allow us to deliver certified trenchless technologies backed by global expertise and local implementation.

Industry-Leading Technology:

Empipe Infrastructure Group maintains licensed partnerships with industry leaders in structural lining technology, ensuring access to the most advanced SIPP systems and materials available.

Proven Experience

Our experience allows us to identify the best SIPP solution for each specific project, providing long-lasting results across municipal, commercial, agricultural, and institutional applications.

Why Choose Empipe for SIPP Applications?

Specialized Expertise

-

33+ years of trenchless rehabilitation experience

-

Advanced robotic application systems for consistency and precision

-

Licensed partnerships with industry-leading SIPP manufacturers

Comprehensive Capabilities

-

Complete assessment to completion service including CCTV diagnosis

-

Multiple SIPP material options matched to specific application needs

-

Structural and protective coating applications under one roof

Safety & Compliance

-

COR certified with specialized safety protocols

-

Professional certifications including IHSA and industry associations

-

Hazardous environment expertise including confined space and chemical exposure protocols

The CIPP Installation Process

1. Infrastructure Assessment

Robotic CCTV inspection and structural analysis determine optimal SIPP material and thickness specifications.

4. Immediate Cure

3-6 second cure time provides immediate structural integrity and chemical resistance.

2. Surface Preparation

High-powered cleaning and surface preparation ensure optimal adhesion and cure performance.

5. Quality Verification

Post-application inspection confirms proper coverage, thickness, and structural performance.

3. Material Application

Precision robotic spray application delivers consistent thickness and coverage across entire pipe interior.

SIPP vs. CIPP: Choosing the Right Solution

Choose CIPP When:

-

Longer pipe runs require rehabilitation

-

Cost-effectiveness is primary driver

-

Standard municipal applications with proven track record needs

-

Structural "pipe-within-a-pipe" solution is preferred

Choose SIPP When:

-

Immediate return to service is critical

-

Chemical resistance is primary concern

-

Maintaining full pipe capacity is essential

-

Working with extreme temperatures or corrosive environments

-

Host substrate requires complete replacement

The Importance of Endseals

Both SIPP and CIPP applications require proper endseals to prevent groundwater infiltration and ensure long-term structural integrity. Our specialized endseal systems are engineered to match your chosen rehabilitation method's performance characteristics.

Getting Started with SIPP Solutions

Assessment First Approach

Every SIPP project begins with a comprehensive assessment to determine the optimal material selection and application approach for your specific infrastructure needs.

Consultation Process

Our technical team works closely with your operations staff to minimize disruptions and ensure optimal results, particularly crucial for industrial facilities and treatment plants that require minimal downtime.

.png)